Dr Denise M. Beckles

October 2023

The growing interest in the environment and sustainable development in Trinidad and Tobago and around the region has resulted in a variety of efforts to reduce the use of single use plastics. The Trinidad and Tobago Bureau of Standards has developed, in conjunction with a wide variety of stakeholders, a compulsory standard to support legislation by the GORTT to control the use of expanded polystyrene (EPS) products in the food and beverage sector (TTCS 9, Biodegradable Materials – Food-Contact Single-Use Products for Composting in Municipal or Industrial Facilities – Compulsory Requirements). The standard applies to food contact materials that are designated compostable and/or biodegradable, and is in the final stages of a rigorous developmental process. However, for the standard be fully understood, and properly applied by all stakeholders, some discussion of biodegradable plastics is in order.

Plastics are a large group of synthetic polymeric compounds which are made up of thousands of smaller molecules bonded together to form much larger ones. Plastics have revolutionised our way of living, and can be found in bags, toys, storage containers of all types, construction materials, medical items, the list is almost endless. Plastic is produced in vast quantities, in 2019, it is estimated that 353 million metric tonnes of plastic was produced worldwide and here at home, a 2016 study by Millette et al. estimated that 129, 596 metric tonnes of plastic was imported into Trinidad and Tobago ,

However, the very thing that made plastic so popular, its durability, is the cause of an environmental disaster. The strong carbon-carbon bonds in the polymer backbone of many plastics means that these molecules will not readily degrade in the environment. Plastics persist, and with improper disposal cause widespread pollution. Millette et al. estimate that in 2016, a flow of 96,329 metric tonnes of plastic entered landfills in Trinidad and Tobago, of which 26,000 metric tonnes are PET bottles.2 Around the world and right here in the Caribbean, countries are beginning to push for more sustainable products that do not pose such a risk to the environment. Single use plastic items like straws and shopping bags as well as Styrofoam is banned in many places, and to replace these items more sustainably, the use of bioplastics is becoming more and more prevalent. Global production capacity for bioplastics is increasing, with about 2.1 million metric tonnes produced globally in 2019, and growth estimated at 15% by 2024.

Putting “bio” or “green” on a product is a hot marketing strategy right now, as more people look to a more sustainable lifestyle. Unfortunately, not all “bios” are the same, and consumers must be aware of the differences, so that they can make informed purchasing and usage decisions.

United Nations Environment Programme. 2023. Turning off the Tap. How the world can end plastic pollution and create a circular economy. Nairobi. https://wedocs.unep.org/bitstream/handle/20.500.11822/42277/Plastic_pollution.pdf?sequence=4.

Millette, S., E. Williams and C. Hull. 2019. Materials flow analysis in support of circular economy development: Plastics in Trinidad and Tobago. Resources, Conservation and Recycling. 150: 104436. https://www.sciencedirect.com/science/article/abs/pii/S0921344919303313.

European Bioplastics, https://www.european-bioplastics.org/market/.

Bioplastics are a large group of plastics that may be produced from biological materials, either fully or in part. Other bioplastics may be created synthetically, but they can be metabolised by microorganisms into biomass and carbon dioxide. More important to how manufactures and distributors label their items, and how consumers choose and dispose of bioplastic items however, is how the material behaves in the environment.

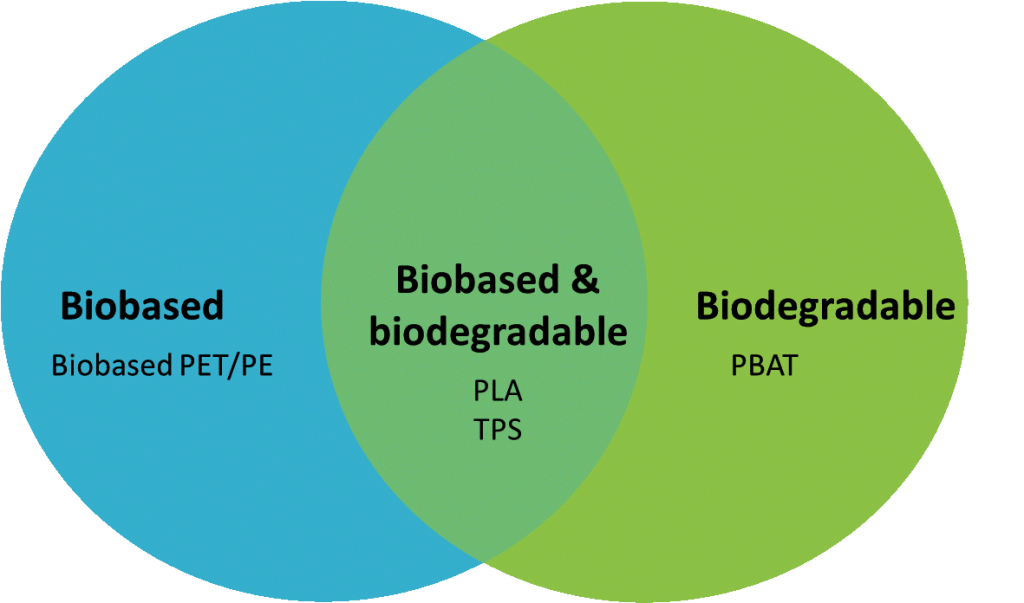

Bioplastics can be biobased, but not biodegradable. These are materials that are created fully or partially from biological materials, yet cannot biodegrade in the environment in a reasonable timeframe. Examples would include biobased polyethylene terephthalate (PET) and polyethylene (PE) materials; these products utilise the biological material in their production to reduce fossil fuel and petrochemical plastic use, but cannot biodegrade in the environment. These materials can be used in every way like their original petro-based plastic versions.

timeframe. Examples would include biobased polyethylene terephthalate (PET) and polyethylene (PE) materials; these products utilise the biological material in their production to reduce fossil fuel and petrochemical plastic use, but cannot biodegrade in the environment. These materials can be used in every way like their original petro-based plastic versions.

Or, bioplastics can be biodegradable, but not biobased. These materials are manufactured entirely from synthetic materials, but when exposed to the correct conditions in the environment, may be biodegraded by bacteria to produce carbon dioxide, water, and biomass. One example is polybutyrate adipate terephthalate (PBAT); flexible and tough, it can substitute for low and/or high-density polythene (LDPE/HDPE) and can be used in garbage bags, wrapping films and disposable plastic products like cups.

And just to add to the confusion, some bioplastics are both biobased and biodegradable. These materials maybe manufactured entirely or in part from biological materials, and can also be degraded by bacteria. For example, polylactic acid (PLA) is made from fermented starches, and can be substituted for a wide range of petro-based plastics, and is commonly used in food and beverage containers. Thermoplastic starch (TPS) is made by heating starch with water and plasticisers, it can also be used in food and beverage packaging, one-time use items like utensils as well as biodegradable packing peanuts and protective films.

It is important to note that just because a material says it is 100% derived from biological sources, it does not mean that it is biodegradable. So when an item is labelled as ‘biodegradable’, what does that really mean? Three terms that are commonly used interchangeably are biodegradable, compostable and oxo-degradable. However, they are not all the same.

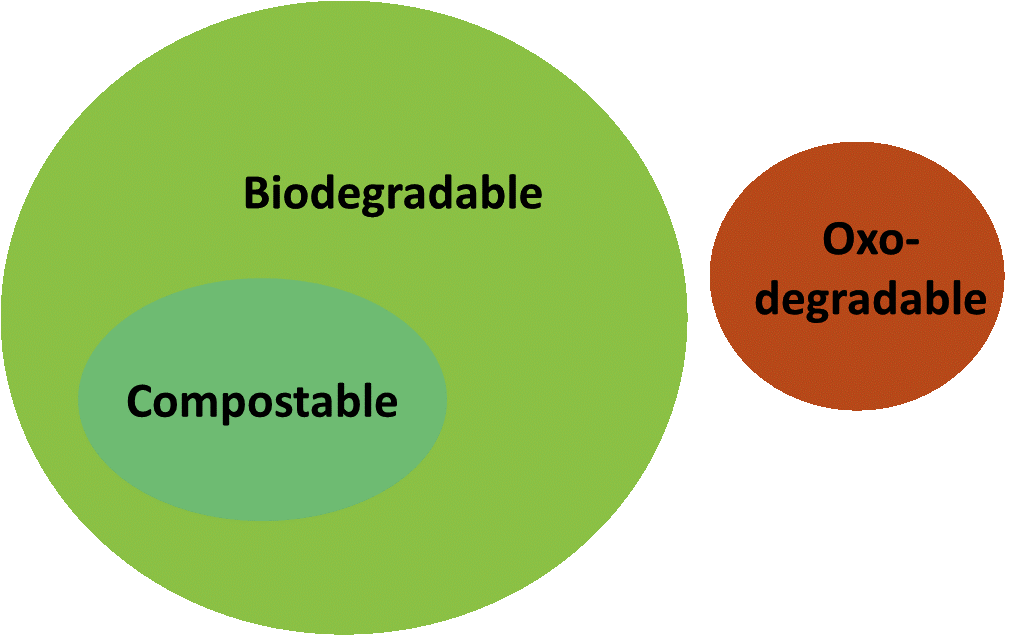

Biodegradable materials are those that can be metabolised by microorganisms into organic biomass, carbon dioxide or methane, inorganic compounds and water. Compostable materials are those that are ‘able to be biodegraded in a composting process without leaving any visible, distinguishable or toxic residue; and under managed conditions, inclusive of, temperature, humidity and time-frame, in a composting facility’.4 A key point to note is that a compostable material must be biodegradable under specific conditions, usually under those that are found in industrial or municipal composting facilities; which is well illustrated in the title of the draft standard.4

TTCS 9, Biodegradable Materials – Food-Contact Single-Use Products for Composting in Municipal or Industrial Facilities – Compulsory Requirements. Draft standard.

Oxo-degradable materials are those that are ‘designed to break-down by accelerated oxidation and fragmentation through the addition of chemicals under the action of oxygen and UV light or UV light and heat’.

This illustration shows how these three terms are associated, and make it clear that they are not interchangeable. While all compostable materials are biodegradable, not all biodegradable materials are compostable. The speed at which the degradation occurs and the conditions that are required play a role in how these materials are defined. Oxo-degradable materials are neither biodegradable nor compostable. Oxo-degradable materials are not actually biodegradable – they are regular plastics that are treated so that they will disintegrate on exposure to oxygen. The plastic material breaks into smaller pieces, but is not converted to biomass, water and carbon dioxide. The breakdown of oxo-degradable plastics is a source of microplastic which is becoming a major environmental problem. Microplastics are found everywhere, are getting into food systems, and the long-term effects are not yet known.

materials are compostable. The speed at which the degradation occurs and the conditions that are required play a role in how these materials are defined. Oxo-degradable materials are neither biodegradable nor compostable. Oxo-degradable materials are not actually biodegradable – they are regular plastics that are treated so that they will disintegrate on exposure to oxygen. The plastic material breaks into smaller pieces, but is not converted to biomass, water and carbon dioxide. The breakdown of oxo-degradable plastics is a source of microplastic which is becoming a major environmental problem. Microplastics are found everywhere, are getting into food systems, and the long-term effects are not yet known.

There are significant implications for disposal of biodegradable polymers and bioplastics, as while they can biodegrade, they require specific conditions to do so quickly. These conditions generally include aerobic conditions, with good moisture and appropriate nutrients for the microorganisms to raise the compost temperature high enough to do their work in the most efficient manner. Biodegradable plastics that end up in a landfill, buried under a mountain of municipal trash will degrade faster than regular plastic, but the process could take months or even years. Bioplastics that end up in the environment however, may not degrade at all. For example, polylactic acid (PLA) does not degrade in seawater. A 2017 study in Germany showed that PLA did not degrade at all after one year in a simulated sea or fresh water environment. On the other hand, another study demonstrated 10% mineralisation of polybutyrate adipate terephthalate (PBAT) in soil over a 6-week period. This is of concern, as having a ‘bio’ or ‘biodegradable’ label on a package may have an undesired effect; consumers may believe that because the material is biodegradable, they can dispose of it indiscriminately, and it will “degrade”. Unfortunately, this is not the case for most bioplastics, and may inadvertently result in increased littering.

[1] Bagheri, A.R., C. Laforsch, A. Greiner and S. Agarwal. 2017. Fate of So-Called Biodegradable Polymers in Seawater and Freshwater. Global Challenges, 1(4):1700048. https://onlinelibrary.wiley.com/doi/full/10.1002/gch2.201700048.

[1] Zumstein, M.T. et al. 2018. Biodegradation of synthetic polymers in soils: Tracking carbon into CO2 and microbial biomass. Science Advances, 4:eaas9024. https://www.science.org/doi/10.1126/sciadv.aas9024.

For further information on the topic contact:

Dr Denise Beckles, Senior Lecturer in Environmental Chemistry, Department of Chemistry, Faculty of Science and Technology, The University of the West Indies, St Augustine

Tel: 868-662-2002 Ext. 83534,

Email: denise.beckles@sta.uwi.edu

For further information on the National Standard for Biodegradable Products contact:

Adrienne Stewart, Standards Officer II, Trinidad and Tobago Bureau of Standards

Tel: 868-662-8827 ext 2048,

Email: adrienne.stewart@ttbs.org.tt